Usage Instruction (Service): The combustion system managed by the company Perfect Combustion Sdn Bhd has the feature of being performed by professionally competent and experienced electricians to make sure that you obtain excellent outcomes. A number of measures are generally necessary when operating a combustion system:

- Select the proper energy for the combustion engine. This might be determined by considerations that include price, accessibility, and the effect on the environment.

- Check that the airflow is enough for the ignition cycle. You may need to alter the ventilation circulation rate or add a filter to the ventilation system to eliminate impurities.

- Begin the burning process by sparking the fuel-air combination. This can be performed independently or with an automation system's help.

- Keep an eye on the method of combustion to guarantee that it is running effectively and efficiently. This might include taking measurements of the emissions' humidity, strain, and chemical makeup.

- Make any required adjustments to the engine in order to improve functionality and reduce pollutants. This might entail altering the fuel-to-air balance or inserting extra machinery like a converter for catalytic reduction.

- Repair and examine the whole thing continuously to guarantee proper operation and avoid malfunctions or security problems.

In the long run, the functioning of a combustion system necessitates extreme dedication to every aspect and a complete grasp of burning and energy transport concepts. These devices must have Adequate education and expertise to operate safely and effectively.

Service Location: A pleasant surprise for everyone who lives within or surrounding Selangor Darul Ehsan! Considering over a decade of company knowledge, we at Perfect Combustion Sdn Bhd provide a hob and combustion system that is nothing short of chef's kiss quality! Simply tell us where you are in Selangor - Klang Valley, Kajang, Bangsar, Rawang, and so on - and we will be present to assist you. Call us by any means of correspondence or message mode that you like, and our staff will set up an appropriate moment and day for you within as little time as practicable.

Operation: The technique of igniting elements in an environment full of oxygen to create warmth and power is called a combustion system functioning. An energy origin, an air availability, and an ignition container whereby fuel and air combine and burn are common elements of an assembly. The substance being burned is usually in the shape of a solution or gas, fed to the chamber where it burns via an inlet or regulator. A secondary intake controls the air availability, which is sent to the room where combustion occurs. Within the combustion space, oxygen and fuel combine and are started via an electrical current or blaze.

When the fuel blisters, thermal radiation is released. It is then transported to a thermal converter or immediately to the atmosphere around it. The combustion merchandise, which includes carbon dioxide, liquid vapour, and additional chemicals, is subsequently evacuated from the circulatory system. A combustion system's functioning is vital to a lot of different sectors, particularly the manufacture of electricity, travel, and industry. To guarantee effective and ethical functioning, constant surveillance and oversight are required.

Combustion System Overview

Combustion, more commonly referred to as burning, is the fundamental method of chemistry through which power is released through an air and fuel combination. The start-up and burning of the gasoline happen throughout the motor itself when using the case of an internal combustion engine. The heat generated from burning is then primarily converted into mechanical power by the combustion process. The internal combustion engine is made up of a stationary chamber and a piston that is rotating. The cylinder's piston is pushed by the increasing burning chemicals that turn the shaft of the engine. This action eventually powers the car's tyres via gearing in the machine.

There are two types of fuel-injected engines in use today: spark-injection petrol engines and ignition systems with compression diesel engines. Most of them are 4-stroke round motors, which require four piston strokes to finish the process. There are four separate steps in the phase: intake, enlargement, burning and energy stroke, then emission.

Flash combustion combustion engines and compression-ignited diesel generators operate differently in terms of supplying fuel and combustion. Throughout the induction phase of an engine using dash ignition, gasoline is combined with oxygen before being inhaled into the combustion chamber. The spark burns the fuel-air combination when the cylinder crushes it, resulting in burning. Throughout the engine's stroke, the piston's motion is pushed by the enlargement of the gaseous mixture. Just air is introduced and then squeezed by a diesel engine. Engines powered by diesel next shoot a precise amount of gasoline into the heated air under compression, enabling it to catch fire.

We offer excellent support and craftsmanship for every one of your power tasks. Examples of these services are urgent call-outs, residential plugins, workplace refurbishments, residential lightning assessments, rewires, or electrical inspections. Each of our electricians is highly certified and performs their duties in compliance with the Institute of Electrical Engineers (EE) requirements. The Hall serves various cuisine and beverages, featuring handcrafted baked goods, wood-fired meals, hamburgers, sirloin sandwiches, tapas, roasted chicken, fish with chips, and a better experience. Having so many options, there indeed are options for everybody!

Even with the scale of the task, Barton Knight Electrical offers uncompromised wiring layout, setting up, and inspection services. We are going to make sure that every job complies with current electrical regulations and regulatory requirements, and our satisfaction assurance backs every bit of our efforts. PERFECT provides entire built specifically combustion systems as well as machinery constructed in accordance with current guidelines and requirements for every purpose in stoves, clothes dryers, burning facilities, and burners.

A whole burning system comprises a burner, a pipe train, a management board and, if necessary, an ignition chamber. Every device is function-tested before delivery to guarantee an effortless inception. Tailor-made solutions created in tight collaboration with the client enable simple installation. According to the programme, client specifications, and regional laws, the ultimate burning engine could rely on a variety of forms and combinations. PERFECT will deliver every necessary certificate and release with the machinery to ensure a seamless changeover on arrival.

About Perfect Combustion Sdn Bhd

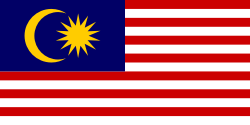

Perfect Combustion Sdn Bhd was founded in 1997 and has over ten years of expertise in industrialised burner, bundled burner, and combustion system operations which include boiler, furnace, and incinerator, along with flame transformation operations. Selangor, Malaysia, is the location of the firm. We belong to a career in engineering advertising and service organisation that is well acknowledged and valued by individuals it works with as a challenge fixer that provides clients with a single point of contact. The firm concepts, supplies, installs, and commissions oil and gas ignition systems and energy-producing technology in Malaysia and South East Asia.

Combustion System Specification(s):

- Has the feature of being performed by professionally competent and experienced electricians to make sure that you obtain excellent outcomes

- Situated in Selangor Darul Ehsan

- Performed by more than ten (10) years of experienced electricians

- Solely Malaysian-based

- Port Klang